How to Set Up a Shop Drawing Review Process: A Comprehensive Guide (with Free Template)

05 Oct

Table of Contents

ToggleManual processes, poor communication, and delays in the shop drawing review process can cost you—both time and money. You know it.

What are Shop Drawings?

Shop drawings are detailed construction documents created by subcontractors and suppliers to illustrate the fabrication, assembly, and installation of building components.

They bridge the gap between design and construction, ensuring materials, components, and assemblies align with architectural and engineering specifications.

Why is A Shop Drawing Review Process Important?

A well-structured shop drawing review process helps construction teams:

- Prevent costly errors before installation

- Ensure compliance with design intent

- Improve coordination between stakeholders

- Reduce delays in project timelines

- Minimize rework and RFIs (Requests for Information)

Without an efficient review system, overlooked errors in submittals can lead to project delays, material wastage, and budget overruns.

💡 Pro Tip: Standardizing your shop drawing review workflow using a digital document review system can reduce errors by up to 30% and improve project efficiency.

Related: The Role of Quality Assurance in Construction Document Reviews

Who Are the Key Stakeholders in the Shop Drawing Review Process?

The shop drawing review process involves multiple stakeholders, each playing a vital role in construction document reviews and contractor submittals:

- Design Architect/Engineer and Consultant: Specifies items requiring shop drawings and reviews them for conformity with design intent.

- Project Manager: Ensures completeness and timeliness of shop drawing reviews, negotiates timeframes, and tracks submissions.

- Contractor: Coordinates and submits shop drawings, ensuring compliance with specifications, and distributes reviewed drawings to originators (subcontractors and suppliers).

- Subcontractor: Prepares and submits shop drawings to the contractor, ensuring they align with specifications and design intent.

Related: How to Automate Submittal Workflows to Streamline Reviews

How to Set Up a Shop Drawing Review Process

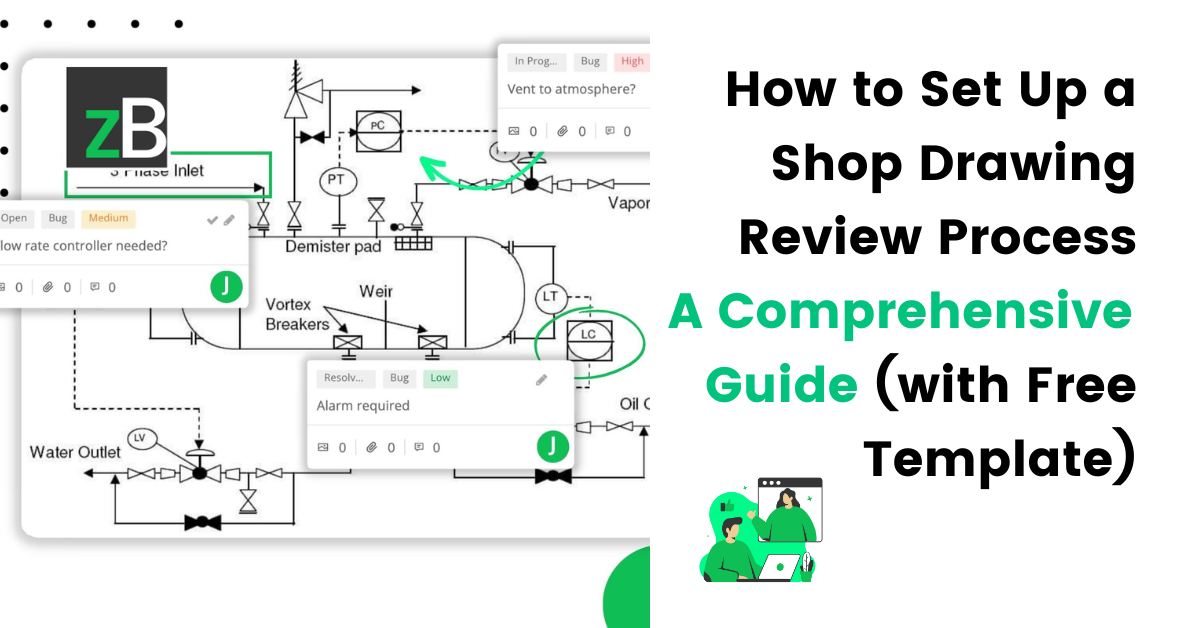

While shop drawings vary by project, the shop drawing review process follows a standard workflow. Here’s a step-by-step guide to setting up an efficient document approval workflow:

Step 1: Create a Submittal Schedule

Contractors must develop a submittal schedule based on the project’s product specifications, ensuring deadlines align with the overall timeline. This schedule should include:

- Deadlines for shop drawing submissions

- Review and approval turnaround times

- Buffer time for revisions and resubmittals

[Free Template]

Submittal Schedule

Get a free copy to create a Submittal Schedule with ease and stay on top of your tasks and timelines.

Download YoursStep 2: Define Design Delegation & Responsibilities

Design delegation clarifies the roles of architects, engineers, and contractors in the shop drawing review process. Contractors must:

- Identify which shop drawings require review by a delegated design engineer.

- Ensure specifications outline engineering review requirements, including licensing and liability coverage.

💡 Tip: Clearly define responsibilities in contract documents to avoid disputes.

Step 3: Contractor’s Review of Shop Drawings

Here, contractors assess shop drawings for constructability, verifying feasibility, materials, and alignment with the construction schedule.

💡Pro-Tip: Avoid batch submissions. Submit drawings in phases to prevent review delays.

Srep 4: Architectural & Engineering Review for Design Intent

Now, architects and engineers review shop drawings to confirm alignment with design intent—not to make design changes.

[Free Template]

Submittal Review Checklist

Get a free copy of the Construction Submittal Review Checklist to save time and complete submittal reviews faster.

Download YoursStep 5: Handling Revisions & Supplemental Instructions

If discrepancies arise, reviewers should:

- Issue supplemental instructions (SI) for clarifications or changes.

- Ensure contractors incorporate feedback and resubmit drawings.

- Track and document changes for audit purposes.

Step 6: Confirming Shop Drawing Approval with Stamps

Architects or engineers of record must stamp shop drawings to confirm review completion. The stamp should indicate that the review ensures alignment with design intent, while noting any deviations from the original design.

Step 7: Coordination, Clarification, and Making Changes

During the final phase, contractors must implement necessary changes based on reviewer feedback, ensuring smooth coordination before construction. Collaboration at this stage helps:

- Address site conditions

- Avoid misinterpretations

- Prevent costly delays

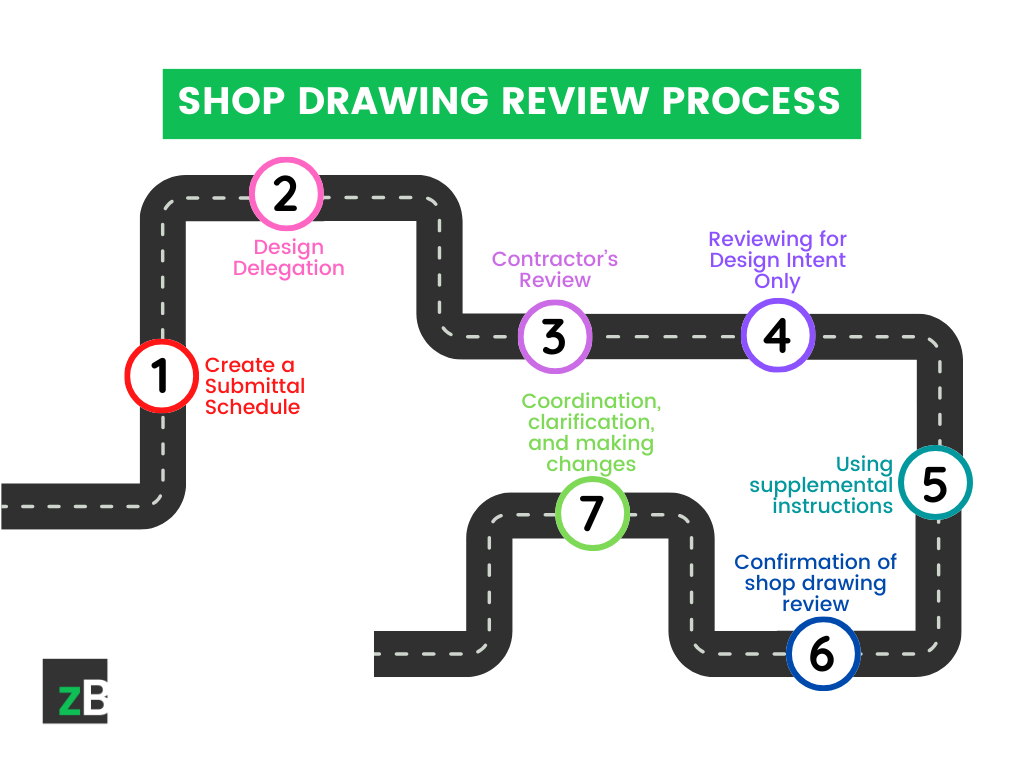

How Does the Shop Drawing Review Process Look Like in Practice?

In real-world scenarios, shop drawings are often reviewed alongside other construction documents like product information, material selections, and mockups. However, this section focuses specifically on the shop drawing review process, which also applies to other submittals.

Typical Shop Drawing Review Workflow:

1. Architect/Engineer → Specifies product requirements and submits them to the contractor.

2. Contractor → Receives specifications and assigns a subcontractor to source the product.

3. Contractor → Creates a submittal schedule aligned with the project timeline.

4. Subcontractor → Prepares and submits shop drawings detailing product use and installation.

5. Contractor → Reviews shop drawings for compliance with specifications. If acceptable, stamps them and submits them with the submittal schedule to the architect.

6. Architect → Reviews drawings against design intent and:

- Approves as noted → If they meet specifications.

- Approves with comments → If minor adjustments are needed.

- Rejects for resubmittal → If they deviate significantly from requirements.

7. Architect → Forwards structural, mechanical, electrical, and plumbing (MEP) shop drawings to relevant consultants for review.

8. Consultants → Review shop drawings for their disciplines to ensure compliance with specifications.

9. Consultants → Return reviewed MEP shop drawings to the architect for final approval.

10. Architect → Conducts a final review to confirm all elements fit within allocated spaces.

11. Architect → Stamps and submits fully approved shop drawings to the contractor.

🔄 Steps 6–11 repeat as needed until final approval.

This structured shop drawing review process ensures accuracy, compliance, and seamless coordination among all stakeholders, reducing errors and project delays.

4 Common Challenges in Shop Drawing Reviews and Their Impact on Construction Projects

Challenges in the shop drawing review process can significantly affect project schedules and budgets. Here are four common issues and their impact on construction projects:

1. Delays in Submittal Reviews

Delays in shop drawing reviews can disrupt project timelines and increase costs. These delays may occur due to:

- Architects or consultants handling multiple projects under tight deadlines.

- External consultants taking longer than expected, as architects have limited control over their review speed.

Such delays can push back construction milestones, leading to extended labor costs and project overhead expenses—a major concern for contractors aiming to stay on schedule.

2. Limited Time to Review Shop Drawings

The time required to review shop drawings depends on factors such as project complexity, the number of reviewers, and coordination among teams. However, contractors often request faster turnarounds, which can:

- Rush the review process, increasing the risk of overlooked errors.

- Impact quality, especially for long lead-time items like electrical equipment or generators, which require more thorough checks.

This can lead to costly design errors, rework, and project delays.

3. Overlooked Errors in Shop Drawings

Errors in shop drawings—such as incorrect measurements, missing details, or design inconsistencies—can lead to:

- Construction mistakes requiring expensive rework.

- Delays in material procurement, causing further disruptions.

When construction document errors go unnoticed, they can escalate into major construction issues, increasing costs and consuming valuable resources.

4. Lack of Coordination Between Stakeholders

Smooth coordination is critical for a successful shop drawing review process. However, miscommunication between architects, consultants, contractors, and subcontractors can result in:

- Conflicting requirements and last-minute design changes.

- Project delays as teams work to resolve discrepancies.

These coordination gaps can increase costs, require rework, and disrupt workflows, impacting overall project efficiency.

Learn More: The Effects of Construction Document Reviews on Project Schedules and Budgets

[Free Template]

Submittal Review Checklist

Get a free copy of the Construction Submittal Review Checklist to save time and complete submittal reviews faster.

Download Yours9 Best Practices to Streamline the Shop Drawing Review Process

A structured and efficient shop drawing review process is essential for maintaining project timelines and preventing costly errors. Here are nine best practices to help streamline the process:

1. Prioritize & Organize Submittals Effectively

Shop drawings are the blueprint for translating design intent into reality. Understanding their importance ensures stakeholders give them the attention they deserve.

Our team prioritizes shop drawings and submittals, ensuring we don’t delay reviews. I only realized how uncommon this was after hearing from many contractors that we handle submittals faster and with more emphasis than most firms.

David Duman, AIA, Architect, Project Manager and Principal @ Quorum Architects

2. Improve Communication & Collaboration

Clear communication among architects, engineers, consultants, contractors, and subcontractors prevents misunderstandings and delays.

Establishing structured collaboration helps address issues early in the review process.

Learn More: How to Ensure Effective Collaboration in Construction Document Reviews

3. Conduct Timely Reviews

Prompt shop drawing reviews help prevent bottlenecks and keep construction schedules on track. Teams should commit to agreed-upon review timelines to maintain efficiency.

Thoroughly check shop drawings for accuracy, completeness, and compliance with project requirements, codes, and standards. Catching errors early minimizes costly rework and construction delays.

5. Continuously Monitor the Review Process

Regular tracking of shop drawing reviews helps identify potential issues before they escalate. Monitoring progress, approvals, and bottlenecks ensures teams stay on schedule.

6. Set Realistic Timelines

Balancing efficiency with thoroughness is key. Contractors should allow adequate time for reviews instead of pushing for rushed approvals.

📌 At Quorum Architects, standard submittal review takes about two weeks, but depending on the project, it can range from 10 days to a week. They communicate these timelines with contractors to ensure alignment.

7. Understand Legal & Contractual Requirements

A thorough understanding of contract responsibilities, dispute resolution mechanisms, and shop drawing obligations prevents legal complications and ensures compliance.

8. Adhere to Shop Drawing Standards

Follow established shop drawing guidelines from organizations like:

- American Institute of Architects (AIA)

- Construction Specifications Institute (CSI)

Ensuring compliance with these standards promotes consistency, quality, and compatibility in construction projects.

9. Leverage Digital Review & Document Markup Tools

Digital tools simplify collaboration, markup, and approvals, reducing reliance on physical paperwork and speeding up the review process.

Learn More: Remote Collaboration in Architecture: Can Architects Work From Home?

To streamline the shop drawing review process, consider these construction document management and collaboration tools:

- BIM Software – Platforms like Autodesk Revit, Trimble SketchUp, and ArchiCAD help create, manage, and review 3D models and shop drawings.

- Construction Management Software – Solutions such as Procore, PlanGrid, and Fieldwire enable real-time collaboration and streamlined submittal reviews.

- Cloud-Based Collaboration Tools – Platforms like BIM 360, Bluebeam Studio, Aconex, and zipBoard provide secure, remote access for reviewing and approving shop drawings.

- CAD Software – AutoCAD and MicroStation allow teams to create and annotate shop drawings with precision.

- Document Management Systems (DMS) – Tools like SharePoint, Documentum, Dropbox Business, and zipBoard offer version control and secure storage for shop drawings.

- Augmented Reality (AR) & Virtual Reality (VR) – AR/VR tools enhance visualization, allowing teams to review shop drawings in immersive 3D environments.

- Quality Control Software – Solutions such as Bluebeam Revu, Adobe Acrobat, and zipBoard provide document markup and collaboration features tailored for construction projects.

- Mobile Apps – Apps like Bluebeam Revu for iPad and PlanGrid enable on-site teams to access and review shop drawings on the go.

- Document Markup Tools – Platforms like zipBoard, Adobe Acrobat, and Bluebeam Revu facilitate document markup and annotations for precise feedback.

- Project Management Software – Microsoft Project, Primavera P6, Newforma, and zipBoard help teams track shop drawing reviews and integrate them into project schedules.

How to Set Up Your Shop Drawing Review Process in zipBoard

Complete Construction Submittal & Document Review Process

zipBoard enables AEC teams to review and approve shop drawings and other construction documents in one browser-based platform.

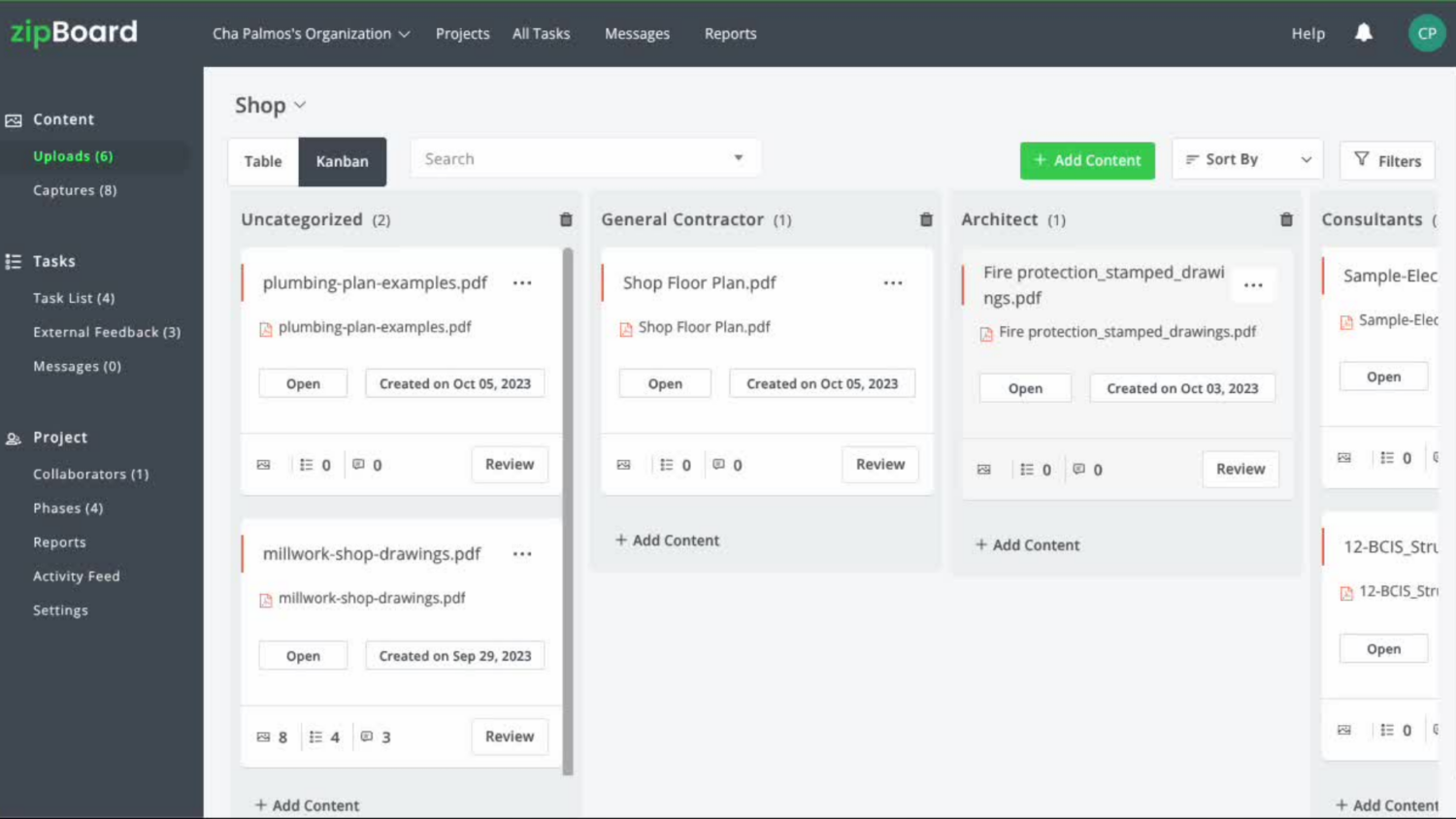

1. Set Up a Project & Upload Shop Drawings

- Log into zipBoard and create a project.

- Click “+ Add content” to upload your shop drawings.

- Optionally, integrate with your DMS via APIs.

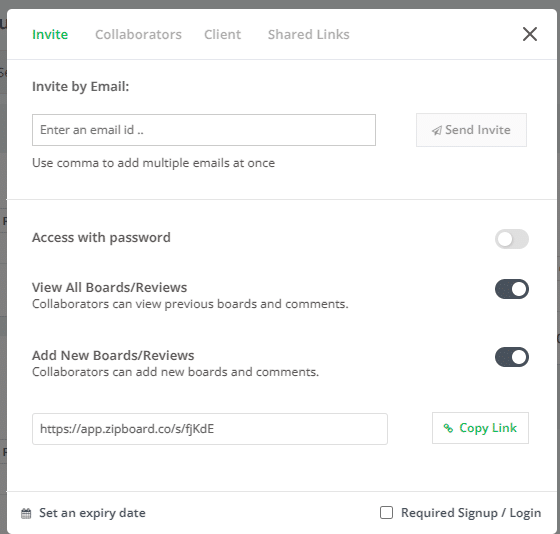

2. Invite Project Stakeholders as Collaborators

- Share your project via email or Collaborators in the left panel.

- Assign appropriate permissions for architects, engineers, and contractors.

3. Create a Customized Workflow

- Use the phases feature in zipBoard to define review and approval stages.

- Assign stakeholders to each phase.

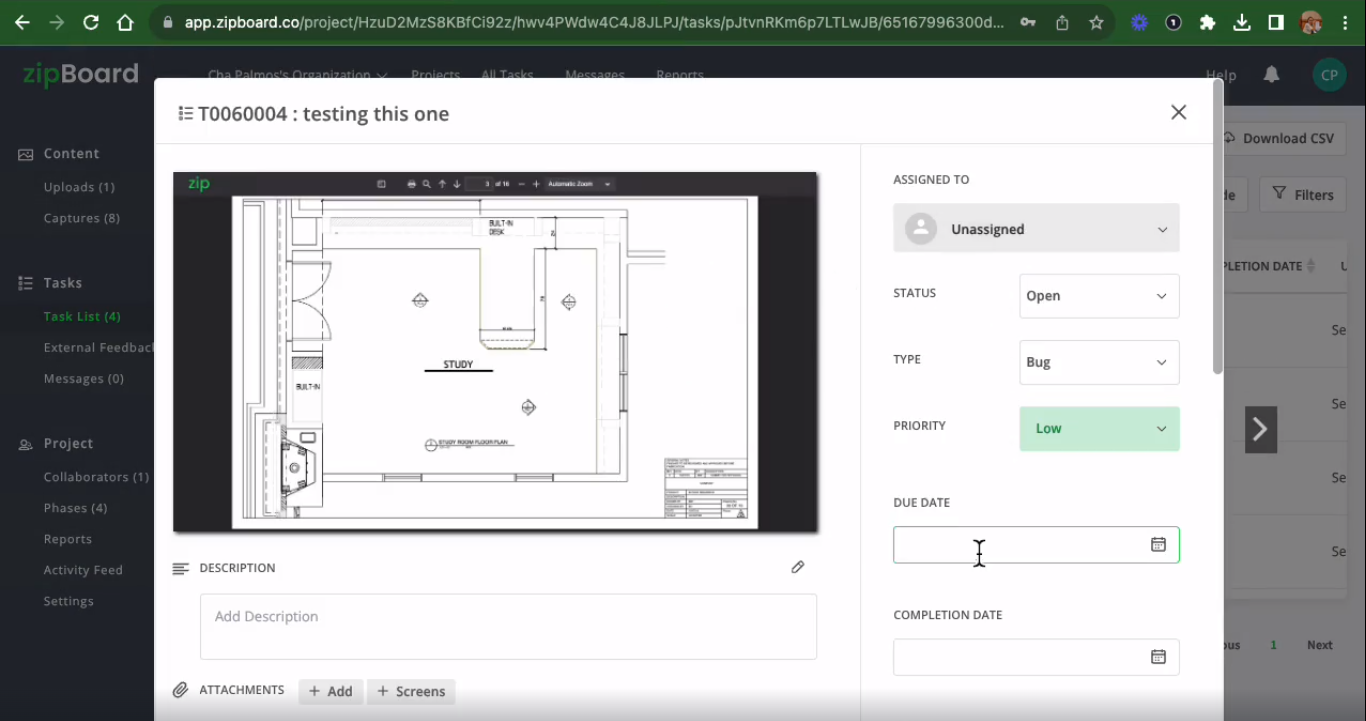

4. Conduct Internal Reviews with Markup Tools

- Architects and engineers can annotate shop drawings using highlighters, text, arrows, stamps, and more.

5. Share with External Stakeholders

- Generate a shareable link for clients and consultants. Follow similar steps as with internal collaborators.

- Adjust access levels for clients by modifying sharing features, as detailed here.

6. Review & Provide Feedback

- External reviewers can comment and annotate shop drawings.

7. Approve Submittals with Stamps

- Architects approve shop drawings with an Approval Stamp or reject them with comments.

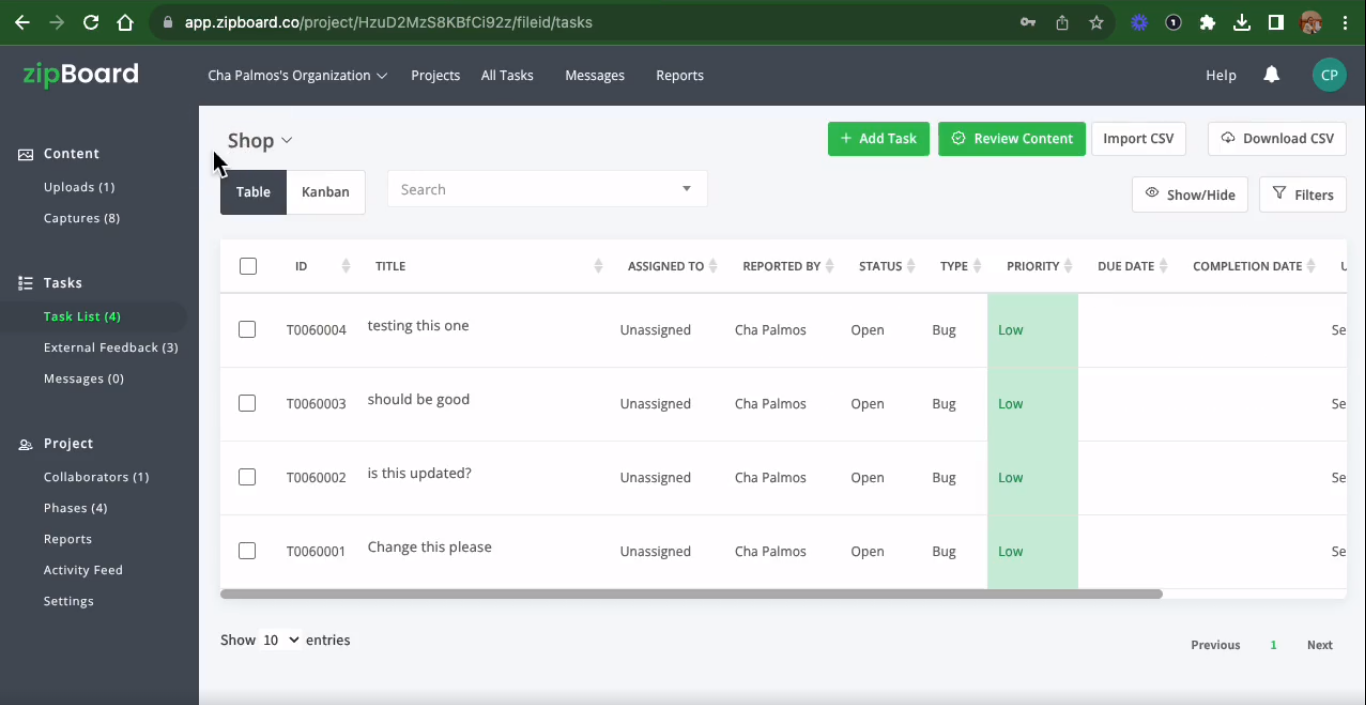

8. Organize and Prioritize Feedback

- Project managers can assign, track, and manage revisions using zipBoard’s Kanban or Spreadsheet views.

9. Make Changes and Resubmit

- Contractors implement revisions and resubmit updated drawings.

10. Final Review & Approval

- The architect rechecks and approves the revised shop drawings.

- Repeat steps 4-10 if further revisions are needed.

Learn more: How to Build a Document Review Hub in zipBoard

Wrapping Up: Why Digital Reviews Improve Efficiency

Delays in the shop drawing review process, manual process and limited time to review shop drawings affect construction project schedules and budgets. But a digital review system like zipBoard simplifies:

- Real-time collaboration across all project stakeholders

- Faster review cycles with digital markup tools

- Automated tracking for approvals & revisions

Simplify Your Shop Drawing Review Process and Improve Collaboration with zipBoard

Start your free trial or book a demo today so that we can create a tailored solution for you.

Book DemoStart Free TrialFAQs

Shop drawings vary based on discipline, including:

- Structural Steel Shop Drawings – Details fabrication and installation of beams, columns, and trusses.

- Architectural Millwork Shop Drawings – Covers custom woodwork like cabinetry, doors, and moldings.

- Mechanical Shop Drawings – Specifies HVAC, plumbing, and fire protection systems.

- Electrical Shop Drawings – Includes wiring, lighting, outlets, and switchgear layouts.

- Plumbing Shop Drawings – Shows pipe layouts, fixtures, drains, and water supply lines.

- Fire Protection Shop Drawings – Maps out sprinkler systems, alarms, and fire extinguishers.

- Curtain Wall Shop Drawings – Details glass panels, framing, and exterior cladding.

- Elevator Shop Drawings – Outlines installation and operation of elevators.

- Concrete Shop Drawings – Covers placement and reinforcement of concrete elements.

- Roofing & Waterproofing Shop Drawings – Specifies materials and installation for watertight systems.

Reviewing ensures compliance with design intent, industry standards, and project specifications, preventing costly errors and delays.

Use a markup and approval tool like zipBoard to review against project specifications. Apply an approval stamp if they meet requirements, or reject them with comments for revisions.

Typically 10-14 days, depending on project complexity and the number of reviewers.

- zipBoard – Collaborative markup & approvals

- Bluebeam Revu – PDF markup

- Procore – Construction management

- BIM 360 – Document control

Sources

- Shop Drawings 101: What Subcontractors Need to Know

- The Shop Drawing Review Process – A Brief Discussion

- A Guide to Shop Drawings: Who Should Review? | Consulting – Specifying Engineer

- Shop Drawings Review Process – Knowledge Areas – NPMS – Real Property – PWGSC/PSPC

- Shop Drawings and Submittals * Timeliness of Submittal Reviews

- Millwork Shop Drawing Sample used in the video on How to Set Up a Shop Drawing Review Process in zipBoard

Author’s Bio:

Dorcas Kpabitey is a Content Marketing Specialist at zipBoard. She began her content marketing journey alongside her BA in Political Science and Spanish degree at the University of Ghana. If she’s not tapping away at her keyboard or spending time on Twitter and LinkedIn, she spends her day reading articles, newsletters and books.

Recent Posts

- User-Friendly E-Learning Review Tools: Trends for Teams in 2026 February 20, 2026

- Your Digital Asset Review Workflow Is Broken (And How to Fix It) February 3, 2026

- Best Practices for Efficient Document Reviews and Collaboration December 18, 2025

- MEP Document Management: How to Streamline Reviews & Avoid Rework October 3, 2025

- What Is Online Proofing Software? And Why Content Review Breaks Without It July 11, 2025

©️ Copyright 2025 zipBoard Tech. All rights reserved.